Innovating Tangible User Interface Design – 3rd year Bachelor 2018

Aim: Explore the design of computationally enhanced objects and tools that integrate physical form and digital functionality in their interaction design

Theme: User-product interaction

Expertise area: Creativity and Aesthetics

Client: Océ

Video: https://youtu.be/Xjo2QM4McH0

Not long

ago most objects and tools used in everyday life had a distinct function and a

physical form resembling this function. Examples of this are a guitar which is

for playing music, or a glass which is for filling with liquids. This has

changed since computing technology has become more common and used for many

things in everyday-life: smartphones, tablets and laptops have countless

functionalities, all packaged into one physical form.

In this project we were challenged to redesign a graphical user interface (GUI)

of the Océ Colorado printer to a tangible user interface (TUI, showcase digital

information in a physical form).

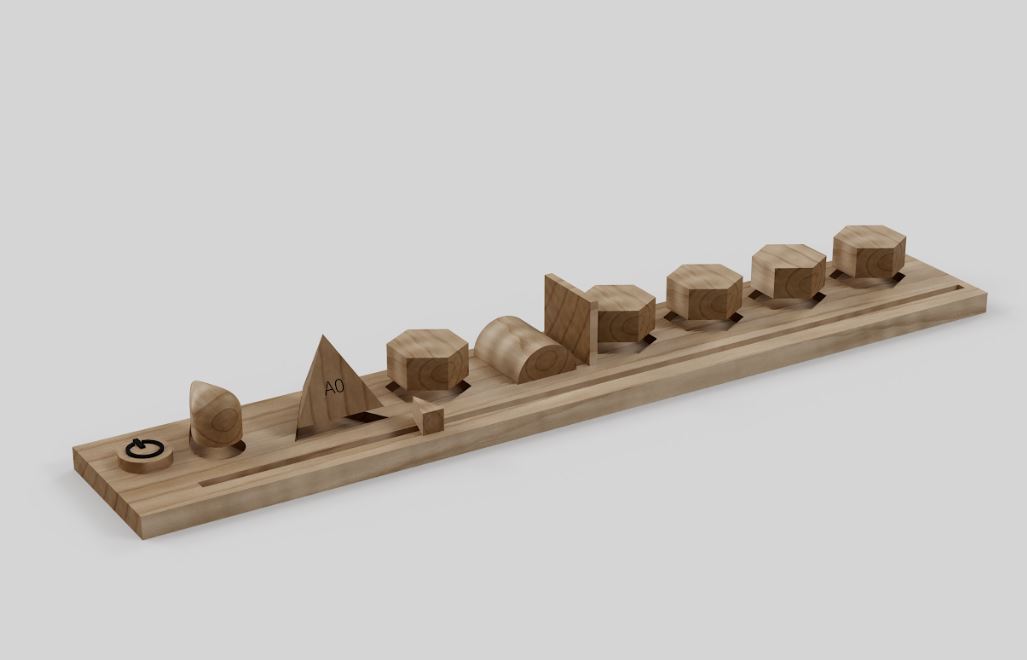

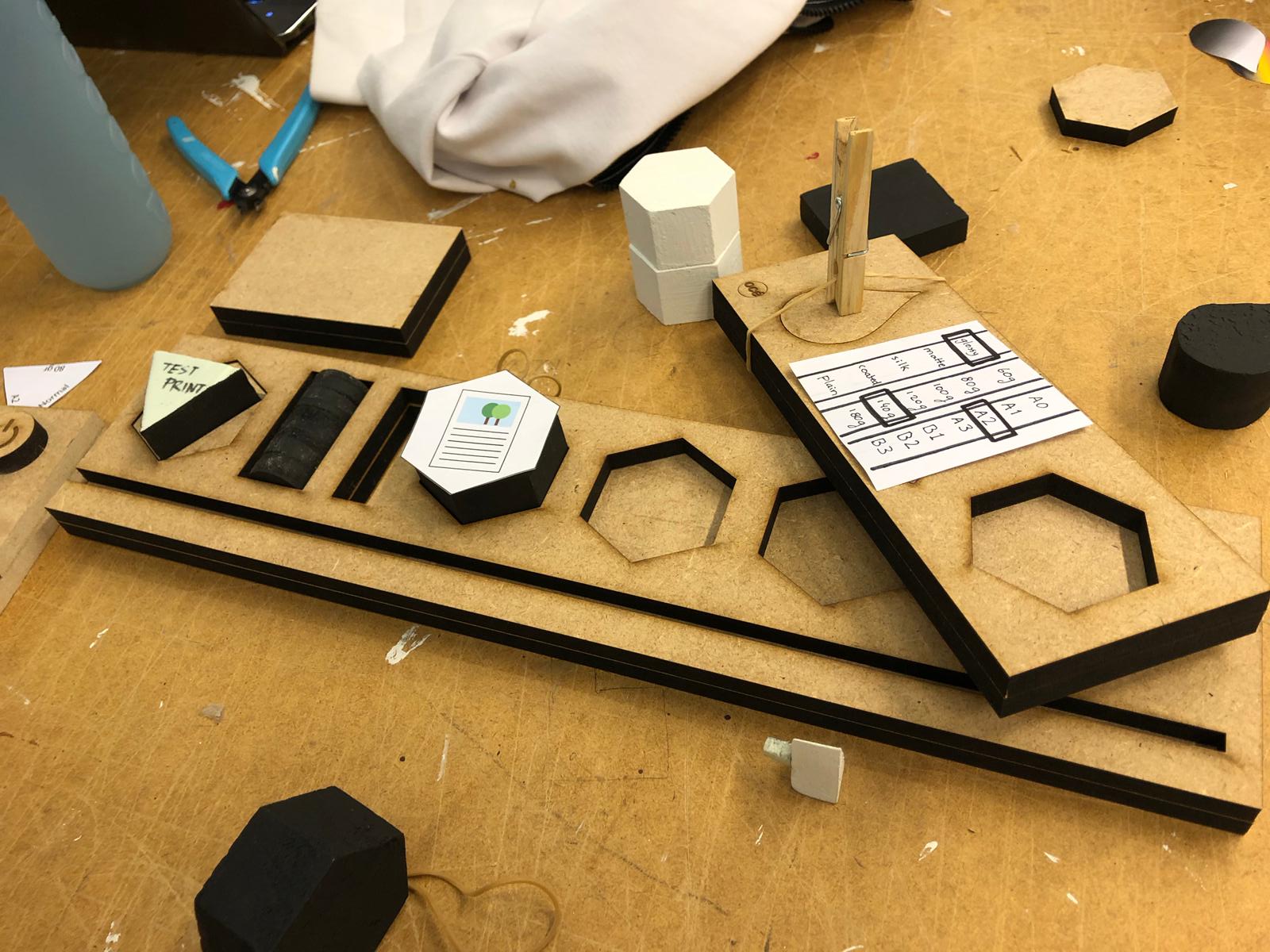

Our final design is a re-design of the whole printshop sequence. Starting at the production manager. The production manager plans the production of the print orders. With their new tangible interface the production manager can load each print on their individual token, they can use the ‘token board’ to set up what type of paper, what paper weight, what paper format, and what color scheme they want for the print. This information will be stored and displayed on the token.

Now the token (alongside other tokens) moves over to the print operator. The print operator will no longer use the GUI to operate the printer but the new TUI, that represents a physical form of the action sequence of the printer. On this sequence board the operator simply places the print token in the sequence. If there occur errors the led strip around the token will start blinking red light and the screen on the token will give the operator more information about the error (e.g. wrong paper loaded), when the error is resolved the led strip will turn green again and the operator can start the sequence.

At last the print will be transported to the finishing department accompanied by the token. This way the employees of the finish department can easily recall information about the print (e.g. size) and, in case of a mistake, can send the still loaded token back to the print operator for a new print. After finishing the print the token will be cleared and brought back to the production manager for re-use.

Leave a comment